Complete INNOVATIVE Screening and Vortex Grit Removal System Technologies

Smith & Loveless’ headworks systems complete unique screening technologies and vortex grit removal systems benefit from our on-going commitment to product research and development, which leads to continued system innovations. Since the introduction of the original vortex PISTA® Grit Chamber in the early 1970s all the way thru to S&L's acquisition of SCHLOSS™ Engineered Equipment in 2015 -- and followed by on-going new product innovation -- no company in the water industry brings more headworks solutions to the market than S&L. This innovation and experience make S&L equipment among the industry’s most specified systems today from new equipment to complete retrofit solutions. S&L offers individual equipment selections to complete packaged solutions.

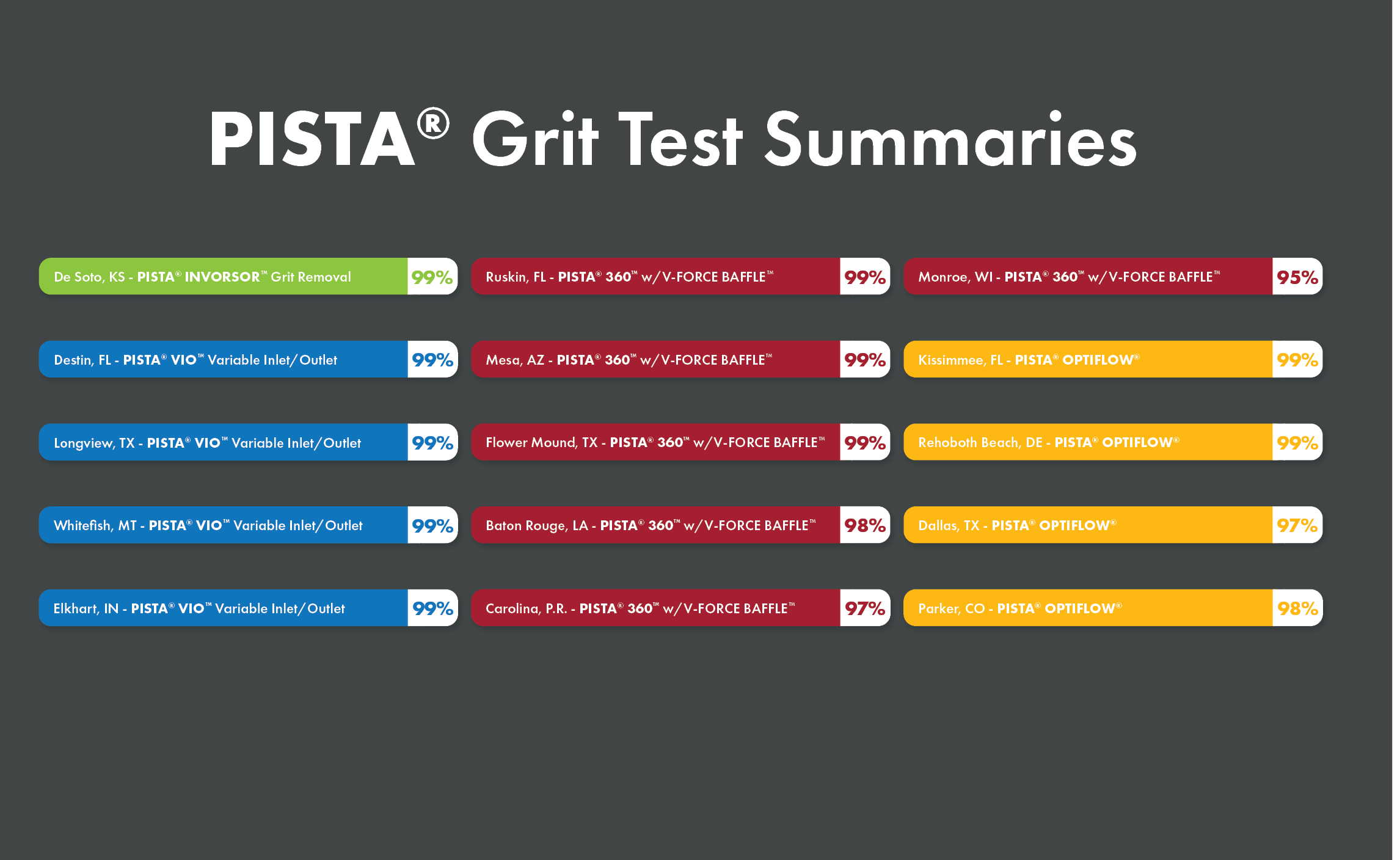

Smith & Loveless' strong reputation in headworks has centered on the PISTA® Grit Removal System line development, which now includes seven different grit chamber technologies offering removal efficiencies tailored for your application, complete grit handling equipment featuring S&L Turbo Grit Pumps, and complete grit washing and dewatering technologies. Complementing these technologies are S&L QUICKSMART™ Touchscreen PLC Controls and product support from pre-design all the way through to installation and post-installation after market service. Our latest grit removal system innovation, PISTA® INVORSOR® introduced in April 2022, becomes the new standard in ultra-fine grit removal: 95% of 75-micron particle grit capture across all flows: low-flow, average flow, and peak flow conditions without derating.

Learn more about our systems by visiting the FAQ section below.

At-a-Glance: Smith & Loveless Headworks Systems

-

PISTA® Grit Removal Systems: Achieve 95% grit removal efficiency down to 75 and 100 microns. Across all flows. Never derated. -

Complete Screening Solutions: SCHLOSS™ Mechanical Bar & Fine Screens, CST Wastewater In-Channel Drum Screens and OBEX™ Fine Screens -

Ideal for municipal wastewater pretreatment and industrial particle applications -

Scalable for new and retrofit applications, and in complete pre-engineered headworks PISTA®WORKS™ solutions