Smith & Loveless developed the packaged treatment concept more than 60 years ago, and continues to develop innovative system designs tailored to meet these essential goals: (1) deliver systems that meet or exceed customer effluent requirements (2) deliver systems that maximize the ease and cost of installation, operation and maintenance (3) minimize footprint requirements.

S&L MBBR-iFAS fixed-film (attached growth) packaged treatment systems meet all three of these goals. S&L packaged MBBR-iFAS systems provide all of the advantages of a conventional MBBR or iFAS system, in a prefabricated tank package. Designed to essentially “plug & play”, the technology is easy to install for customers with urgent and specific treatment system needs, and it reduces the tank size and footprint.

To achieve specific effluent and/or smaller footprint requirements for individual municipal and industrial-commercial application, Smith & Loveless treatment systems are converted to MBBR-iFAS and may be combined with proprietary S&L process zones and equipment components, including:

In-Tank Processes:

- MBBR

- iFAS

- S&L AOAO and Bio-P Multi-Stage Biological Nutrient Removal (BNR) Zones

- Nitrification / Denitrification

- Phosphorous Removal

- Various Aerobic, Anoxic and Anaerobic Zone combinations

- Flow Equalization, Sludge Storage

Post-Treatment:

- S&L Clarifiers

(Hopper-style and stand-alone circular tankage / standard and flocculating) - Chemical Precipitation

- DGF Tertiary Filtration

(Integral or stand-alone tankage) - Disinfection (UV or Chlorination)

- Dissolved Air Flotation

Benefits vs Conventional Biological Treatment Systems:

- Reduced footprint

- Incremental capacity within the same basin by adding more media

(e.g. fill the basin from 30% (by volume) in stage 1 to 50% in stage 2) - Enhanced process stability

- Better handling of variations in flow, temperature, and other influent quality

- Resistant to shock loads

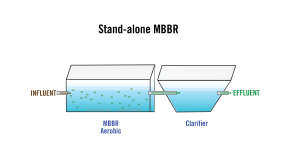

Click to enlarge

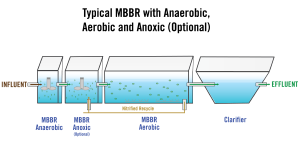

Click to enlarge Click to enlarge

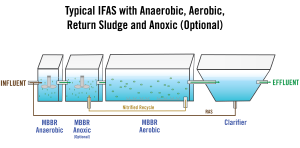

Click to enlarge Click to enlarge

Click to enlarge