Wine caves are growing increasingly popular in California’s wine country — especially in Napa County where there are more than 100 wineries utilizing some kind of wine cave in its operation. Caves provide environmental benefits while preserving land to plant vineyards. And now, one particular Napa winery is setting a new course within this trend: treating wastewater in a cave — treating it FAST.

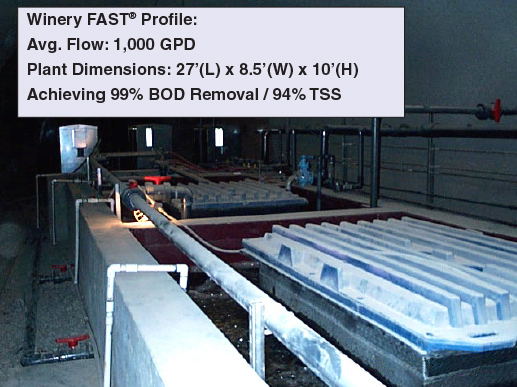

This winery’s state-of-the-art, four-level cave is massive enough to house offices, the entire winery operation, a collection of antique race cars, tasting room, two 12-story elevators, and a high-strength Winery FAST® wastewater treatment system by Smith & Loveless Inc. During the design phase, the winery’s engineering consultant worked closely with Smith & Loveless, the contractor, and state and local authorities to meet the goals of implementing a wastewater treatment system that would maintain a zero water impact on the surrounding community while fitting comfortably in the underground chamber. In 2004, the task was accomplished and the complete winery operation was on-line, including the Winery FAST® system.

Flow Scheme

Waste streams from operations collect in a wet well/holding tank where it is then pumped through a rotary screen into an equalization (EQ) basin. The equalized flow enters the two-stage Winery FAST® at a rate of 1,000 GPD. When the winery is not going through harvest, the system handles the flow in only one stage, treating the flow to below 50 mg/l. When the crush season begins, the higher strength flow —which can range up to 10,000 mg/l BOD—goes through a second stage FAST® zone. Each zone contains FAST® media, a submerged fixed-film upon which a healthy biomass grows and works to degrade the waste stream’s constituents. Because the bacteria are fixed to the media, shock loads can be more easily tolerated and treated. Additionally, solids are prevented from being washed out, yielding stable, hassle-free operation. The location inside a cave benefits the process because it provides a temperate climate with temperatures continually ideal for the bacteria to operate effectively. Sloughed solids (sludge) collect into a sludge holding zone for further digestion. Periodically, the inert solids are collected and re-used for soil amendments in the vineyard. Meanwhile, the clear, odorless effluent emanates from the system’s small hopper-style clarifier and is stored for eventual re-use by drip-irrigation.

Waste streams from operations collect in a wet well/holding tank where it is then pumped through a rotary screen into an equalization (EQ) basin. The equalized flow enters the two-stage Winery FAST® at a rate of 1,000 GPD. When the winery is not going through harvest, the system handles the flow in only one stage, treating the flow to below 50 mg/l. When the crush season begins, the higher strength flow —which can range up to 10,000 mg/l BOD—goes through a second stage FAST® zone. Each zone contains FAST® media, a submerged fixed-film upon which a healthy biomass grows and works to degrade the waste stream’s constituents. Because the bacteria are fixed to the media, shock loads can be more easily tolerated and treated. Additionally, solids are prevented from being washed out, yielding stable, hassle-free operation. The location inside a cave benefits the process because it provides a temperate climate with temperatures continually ideal for the bacteria to operate effectively. Sloughed solids (sludge) collect into a sludge holding zone for further digestion. Periodically, the inert solids are collected and re-used for soil amendments in the vineyard. Meanwhile, the clear, odorless effluent emanates from the system’s small hopper-style clarifier and is stored for eventual re-use by drip-irrigation.

After more than a year of operation, the Winery FAST® continues to easily meet permit requirements. Sample test results demonstrate BOD reduction of 99% (less than 15 mg/l BOD) and 94% of TSS. Operators report how pleased they are with the system’s ability to handle spikes and its ease of operation—important to any winery so that the making of exquisite wines—not wastewater hassles—can always be the focus.