Learn the ways S&L assists our customers with their pumping projects. Hear amazing stories of efficiency, safe and easy operation & maintenance, reliability and longevity, including the story of our first three pump stations, built in 1948 — which are still pumping after 65 years!

Rugged S&L Non-Clog Pumps don’t need design gimmicks to efficiently meet the 10 States Standard for 3” (7.6 cm) solids handling. With custom-trimmed dual-port impellers, we pass 3” (7.6 cm) solids and maintain high efficiencies. Rags, wipes and flushables are no match for S&L.

Efficient pump priming allows wastewater pumping to be accomplished at ground level in a safe environment, eliminating confined space entry for all routine maintenance and inspection with S&L's latest innovation, the WaveStart™ Priming System.

Offering the safest pump station access on the market, EVERLAST™ Pump Stations are inspected and maintained without the requirements typically associated with confined space entry, including harnesses, gas monitoring equipment, and multiple personnel.

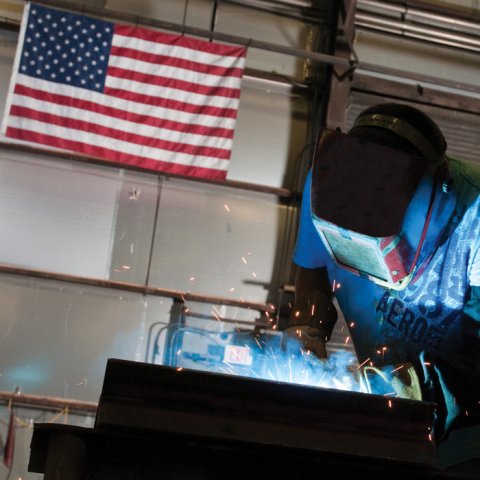

As the industry pioneer of factory-built and assembled pump stations—and single-source responsibility—more than 70 years ago, we continue to develop all of our products in our quality-controlled, U.S. based, 115,000 ft2 (10,600 m2) manufacturing facility.

S&L pump stations are tested to Hydraulic Institute standards in our state-of-the-art automated testing facilities, which replicate actual field conditions including more than 20 feet (6 m) of suction lift. Our customers are always invited to witness testing at our factory.

S&L pump stations are operated without the requirements associated with confined space entry for submersbiles, such as harnesses, multiple personnel and more. This leads to extended service life and 50% less O&M costs for S&L systems – verified by an actual 12-year case study!

Compare the installation requirements for an S&L EVERLAST™ pump station to a typical submersible pump station. The main components and ancillary equipment required for each system are not often included in the submersible “pump purchase price”.

Simplified yet state-of-the-art S&L vacuum priming offers many advantages over self-priming in the key areas of operator safety and convenience, O&M requirements and energy efficiency. Vacuum priming features a less complex design of three basic elements.

Imagine buying an S&L pump station and having it run for 3 generations. That's exactly what the city of Salina, KS did right after World War II. With 70 years of service, our first 3 pump stations have combined for nearly 2 million hours of pumping!

Smith & Loveless has a long and proud legacy of building some of the most energy efficient pumps in the industry. And we'll continue to develop product advancements as technology changes and the market develops.

S&L offers extensive education and training to ensure you get the most out of your pumping system. From direct field service training & local seminars, to online videos & webinars, S&L offers a lifetime of support & education.

Seeing is believing. Smith & Loveless is so confident in our long-lasting, operator-safe Wet Well Mounted Pump Stations (WWMPS) that we bring one with us on the road. Find out more and schedule a visit here.