Smith & Loveless developed the packaged treatment concept more than 60 years, and continues to develop innovative system designs tailored to meet these essential goals: (1) deliver systems that meet or exceed customer effluent requirements (2) deliver systems that maximize the ease and cost of installation, operation and maintenance (3) minimize footprint requirements.

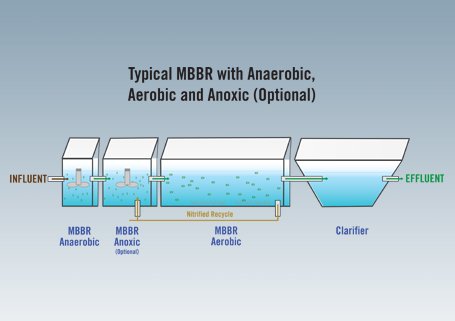

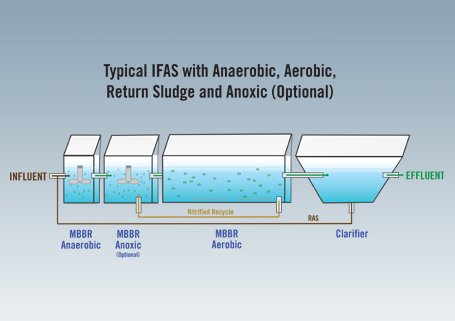

S&L MBBR-iFAS fixed-film (attached growth) packaged treatment systems meet all three of these goals. S&L packaged MBBR-iFAS systems provide all of the advantages of a conventional MBBR system, in a prefabricated tank package. Design to essentially “plug & play”, the technology is easy to install for customers with urgent and specific treatment system needs, and it reduces the tanks size and footprint.

Benefits vs Conventional Biological Treatment Systems:

- Reduced footprint

- Enhanced process stability

- Better handling of variations in flow, temperature, and other influent quality

- Resistant to shock loads

- Incremental capacity within the same basin by adding more media