Tens of thousands of proven Smith & Loveless Non-Clog Pumps convey wastewater around the world, providing reliable service day-in and day-out. Our bold pump design retains several high standards, including oversized bearings and stainless-steel pump shafts, bronze mechanical seals for superior heat dissipation, close tolerances that prevent recirculation and a keyed and tapered shaft for positive lock and easy impeller removal. The result is decades of highly-efficient pumping.

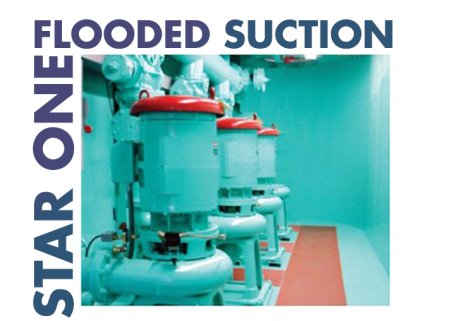

Available in vacuum-primed and flooded suction configurations for above-grade and underground pumping stations or bare pump use, Smith & Loveless Non-Clog Pumps come with trimmed impellers for optimum selection and high efficiency operation. This pump is designed to last.

Now available in sizing up to 12" (300 mm) with premium efficient motors!

| Flows | Up to 7,000 GPM (441 lps) per pump |

| Power | 10 - 300 Hp (7.5 - 225kW) |

| Pumps | 4” - 12” (100-300 mm) |